ProAlert:

Revolutionizing Andon and OEE Monitoring

Turn Downtime Into Uptime. Turn Data Into Action.

ProAlert - Patent Pending, is a leading solution that seamlessly integrates Andon alerting with OEE performance monitoring—empowering manufacturing teams to transform shop floor efficiency.

By combining real-time issue notifications with actionable performance data, ProAlert ensures faster response times, better decision-making, and complete operational visibility. Its flexible, scalable design reduces downtime, strengthens team communication, and supports a culture of continuous improvement—delivering measurable impact from the production floor to executive leadership.

Experience a system that adapts to your workflow, not the other way around.

Andon trees are so... 1980's!

Built for the Realities of Today’s Factory Floor

In a world of global competition, skilled labor shortages, and rising production complexity, real-time visibility is no longer optional—it’s essential.

According to a McKinsey study on Industry 4.0 transformation:

"Digitally enabled lean manufacturing can deliver productivity improvements of 30 to 50 percent.".

ProAlert is your bridge to those gains—without the complexity of a full MES (Manufacturing Execution System) implementation.

What Makes ProAlert Different?

“We reduced scrap, rework, and downtime within weeks of going live.

ProAlert didn’t just give us data—it gave us control.”

— Bryan Frederick, Director of Operations, Reyes Hayashi Automotive

Real-Time Andon Alerts

Empower your operators and supervisors with instant notifications via PA systems, SMS*, email, tablets, or call screens. Trigger escalation flows, log downtime reasons, and assign actions—all from a centralized dashboard.

*SMS can be made available through Twilio, if requested.

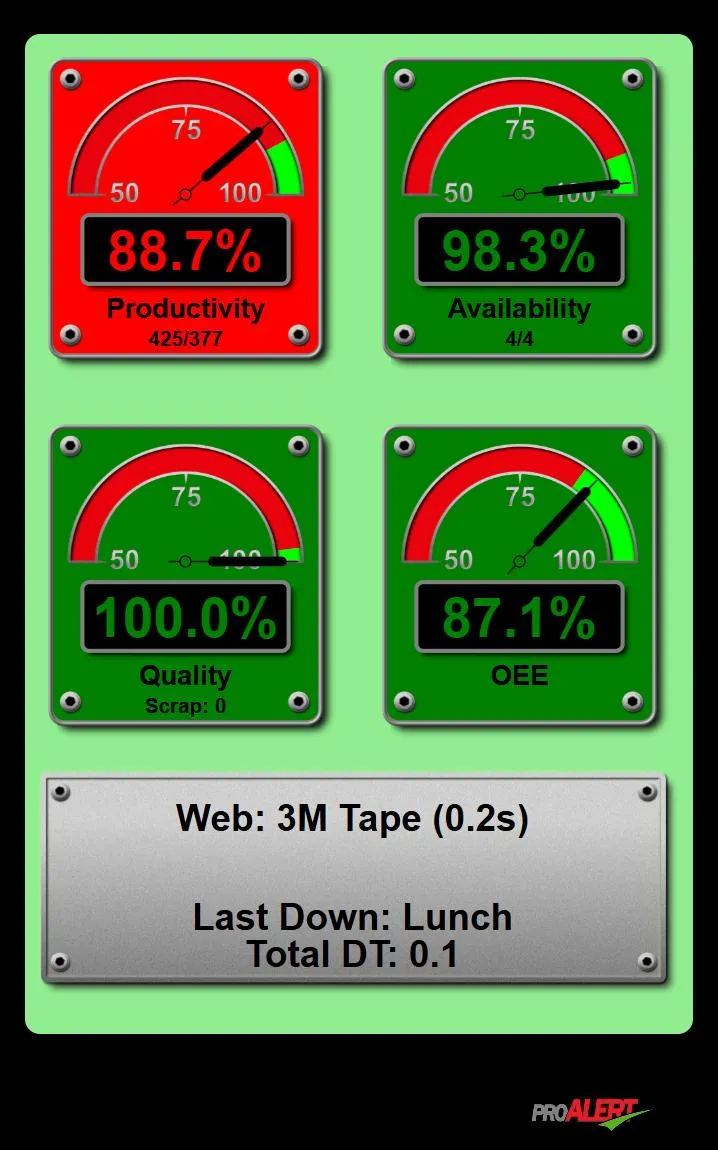

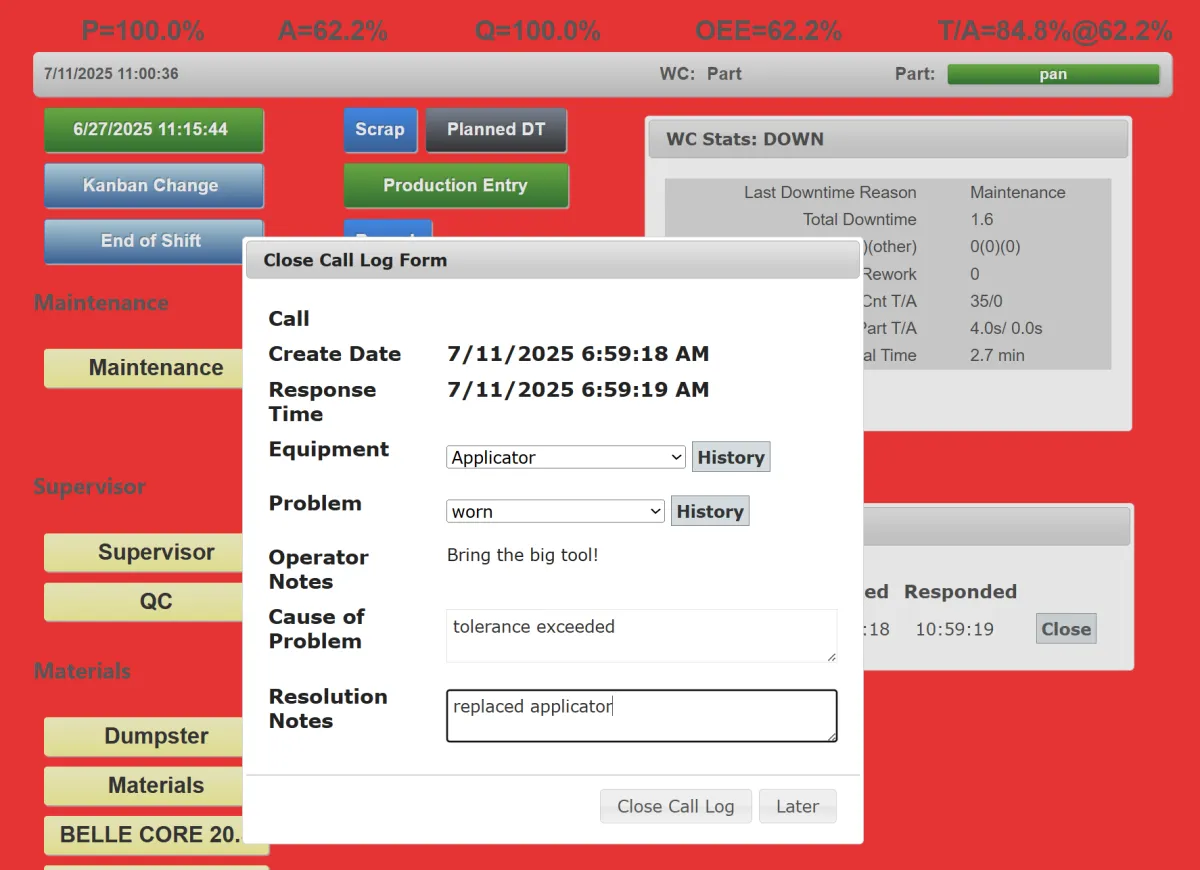

Live OEE Performance Monitoring

Automatically calculates availability, performance, and quality in real time. View line- or team-level metrics, compare shifts, and dig into trends that impact throughput.

Seamless PLC & ERP Integration

ProAlert simplifies shop floor connectivity by providing pre-programmed PLCs ready for deployment. Whether we install them directly on your work centers or guide your team through setup, our solution ensures quick integration with ERPs, spreadsheets, or other systems — eliminating manual data entry and reducing errors.

Mobile Alerts with PAM (ProAlert Mobile)

Material requests, changeovers, and downtime events are instantly broadcast to the right team. Team members can claim tasks, add notes, and keep production moving without delays.

Emergency Mode: One-Tap “Seek Shelter”

When seconds matter, ProAlert switches to a site-wide emergency broadcast mode with alarms, maps, and instructions—keeping your people safe.

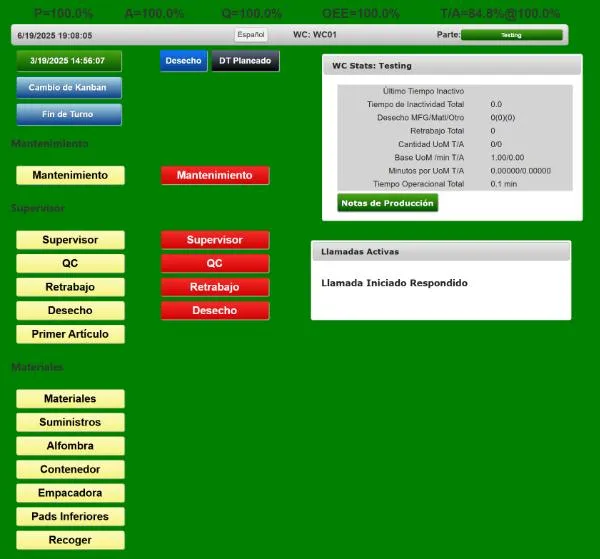

Multi-Language

Work Centers can be uniquely set for user language preference, English, Spanish.

*Other languages available as needed.

English

Spanish

Your Data. Your Rules. Real Results.

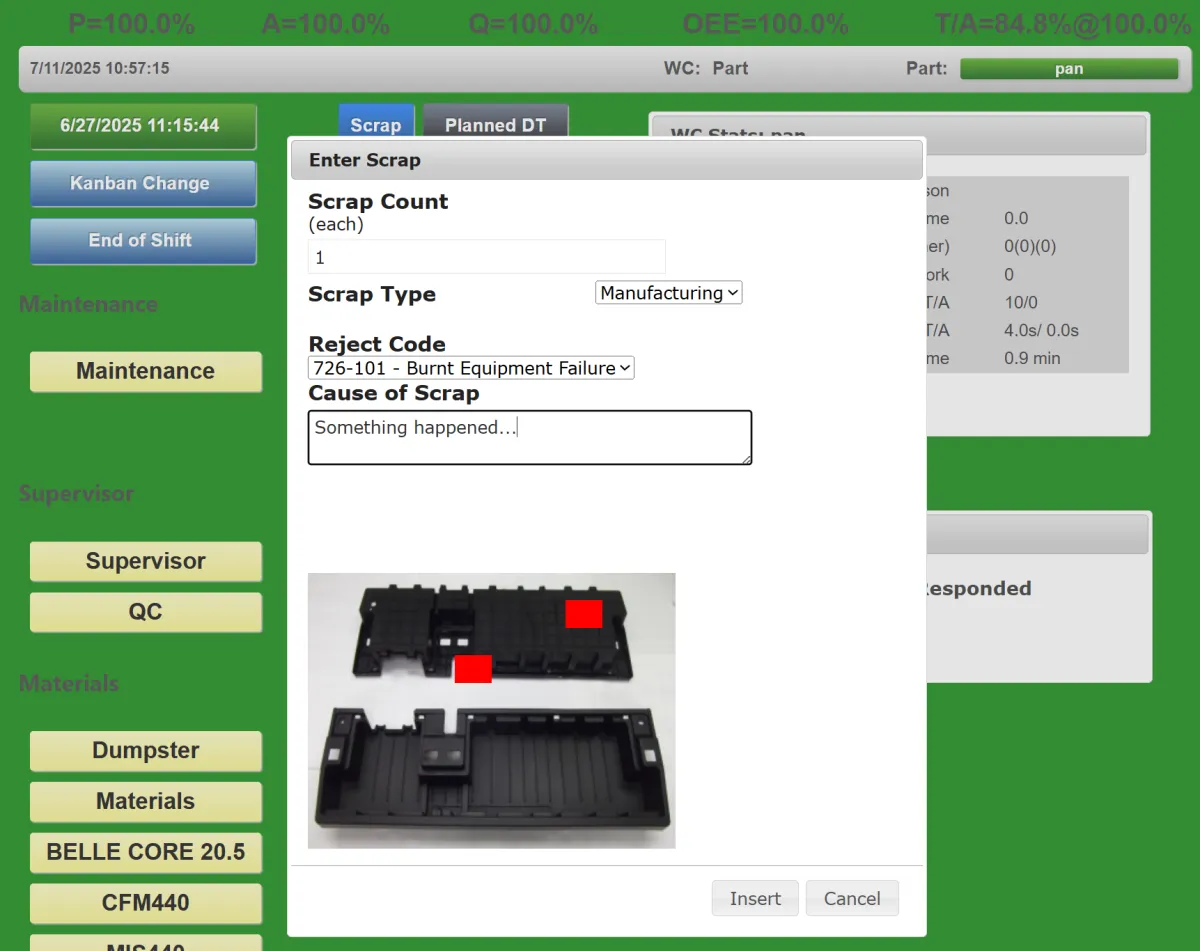

With over 50+ data points automatically captured—including shift timing, cycle durations, scrap type & location, downtime causes, and team response times—ProAlert transforms raw shop-floor activity into clean, actionable insights.

Scrap Type & Location Tracking

Call Log Notes

Designed for Lean, Agile, Growth-Oriented Teams

ProAlert is trusted by discrete manufacturers, automotive suppliers, packaging plants, and food processors looking to:

Eliminate miscommunication and waiting time

Reduce downtime events by up to 30%

Improve shift transitions and accountability

Build a culture of continuous improvement

Want to hear from real users?

Compatible With Your Operational Stack

Turnkey PLC hardware provided for fast, hassle-free deployment

Preconfigured and ready to install

Can be wired by your team or ours

PLCs - Already have PLCs?

ProAlert can also connect with existing hardware from Rockwell, Omron, Siemens, and others—no rip-and-replace required

Integrates seamlessly with ERP and job systems, including SAP, Plex, and Epicor

Flexible data export options, including Excel, CSV, and JSON

Optimized for real-time operations:

ProAlert delivers a mobile-first user experience backed by a SignalR-powered backend. All updates are pushed instantly over lightweight WebSocket connections—ensuring immediate visibility with no page refreshes or delays.

Let’s Get You Started

See ProAlert in action—watch how it can reduce your downtime, boost accountability, and give you the visibility your shop floor has been missing.

ProAlert - incorporates proprietary technology with multiple systems currently patent pending.

Copyright © 2023 - Bridge Software Technologies. All Rights Reserved.

website: CompEdgeSolutions