About ProAlert's Uniqueness

Every day, your shop floor is a living, breathing source of insight—and ProAlert is built to capture every detail. From the moment a shift begins to the final cycle of the day, ProAlert tracks the rhythm of your operations with precision. It records everything from machine changeovers and scheduled breaks to unplanned stoppages and response times. Operator notes, team transitions, and real-time equipment activity are all seamlessly logged to create a complete picture of what’s happening, when, and why.

This continuous flow of data brings your operation into sharp focus. It reveals performance patterns that span shifts, helps uncover the true causes behind downtime and defects, and makes it easy to measure the impact of process improvements over time. Instead of isolated alerts or siloed metrics, your team is empowered with connected, context-rich information that leads to faster decisions and stronger accountability.

When this kind of visibility is paired with ProAlert’s integrated Andon and OEE monitoring, it doesn’t just improve your workflow—it transforms your entire approach to operational excellence.

Data Points

Start/Stop Shift Variance

Did the work center start early or late?

Did they leave early or late?

Time to first cycle

Captured after any planned or unplanned downtime event.

Duration of planned down times (lunch, breaks, meetings...)

Product Change Over durations (Kanban change)

Downtime Event data points

Who initiated

What product is being run

When initiated

How long for help to respond

Who resolved the issue

User-defined hierarchical reasons

Operator notes

Maintenance notes

Test cycles run

Total downtime

Cycle Times

Flexible Data Alignment:

From Plant Floor Teams to Corporate HQ

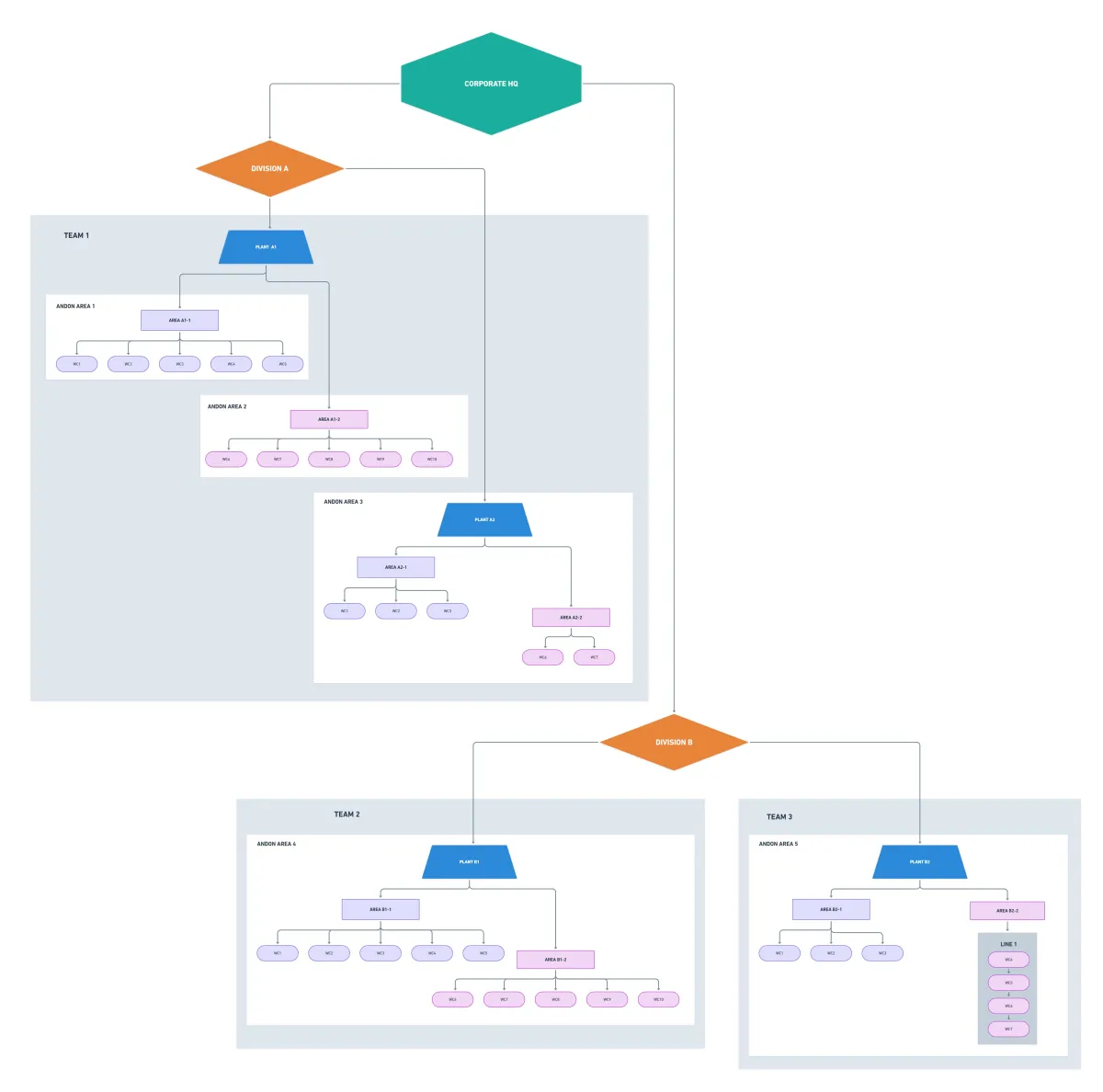

ProAlert’s flexible alignment graphic (below) isn’t just marketing flair—it’s a visual representation of how complete operational visibility travels across every level of your organization. Whether your setup groups Andon zones by shift teams, production areas, divisional units, or entire plants, ProAlert adapts to mirror your real-world structure. This means that frontline operators, supervisors, and plant leaders all see the same critical data—just tailored to their scope. And for corporate headquarters, it provides a consolidated, customized view across all divisions and facilities. This layered visibility enables HQ to recognize which plants are achieving targets, pinpoint systemic inefficiencies across divisions, and support localized improvements with global impact. In short, ProAlert isn’t only about making each segment more efficient—it’s about giving decision-makers at every level the clarity they need, right when they need it.

ProAlert - incorporates proprietary technology with multiple systems currently patent pending.

Copyright © 2023 - Bridge Software Technologies. All Rights Reserved.

website: CompEdgeSolutions